What is the potential of 5G wireless technology for the industry? And how can digitization in production succeed? These are the questions many manufacturing companies ask themselves when it comes to the successful implementation of 5G in production. Through a 5G-Audit, the Fraunhofer-Institute for Production Technology IPT from Aachen now offers manufacturing companies the opportunity to explore their own potentials for the industrial use of the new mobile communication technology and to find out which positive effects 5G can have on existing process flows.

© Мария Ковалевская/stock.adobe.com. The 5G-Audit offers manufacturing companies the opportunity to explore their own potential for the industrial use of the new mobile communication technology and to discover the positive effects that 5G can have on existing processes.

Together with project partners from the fields of production engineering and IT, the Fraunhofer IPT is conducting the 5G-Industry Campus Europe. For several years, the Fraunhofer IPT has been investigating the industrial application of the new mobile communications standard in various research projects. In order to make the technological developments and experiences more easily accessible to interested companies, the institute now offers a modularly structured 5G-Audit. The modules of the audit build on each other, but are freely selectable and can be used both by newcomers who have had no experience with the new mobile communication technology up to now and also by experienced 5G users. The experts of the Fraunhofer IPT thus enable the audited companies to identify their own 5G fields of application, to assess the costs and benefits of 5G integration and to develop concrete implementation strategies. The Aachen researchers can also support the later implementation of the company’s own 5G solutions with practical application knowledge.

The audit modules vary in time and offer companies the option to get to know 5G technology and its potentials and challenges up to the possibility to build a 5G network in their own production halls and integrate it into their existing production line. The Aachen team of engineers and IT specialists also develops ideas for completely new 5G use cases together with the partner companies and accompanies implementation projects, if required, right up to industrial deployment.

“With the 5G-Audit we offer companies in the production field the opportunity to get to know the new mobile communication technology and take advantage of the benefits of 5G. The results of each 5G-Audit are individual recommendations for the individual situation on site in the companies.”, explains Sven Jung, technical director of the 5G-Industry Campus Europe, the concept of the new offer.

Discover the benefits of 5G for production at 5G-Industry Campus Europe

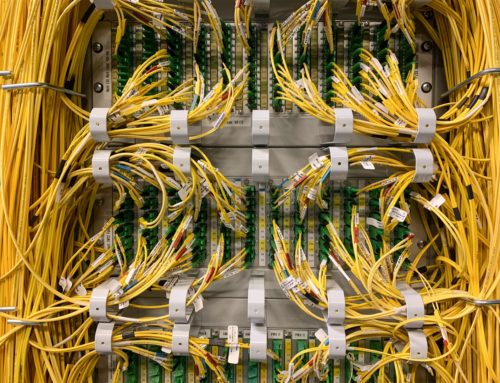

In highly flexible and networked manufacturing systems, all processes and distributed systems must communicate reliably in real time. Only then can manufacturing companies monitor and control their production to a high degree in order to react dynamically to the smallest changes in the production process. With high data rates of up to ten gigabits per second and low latencies below one millisecond, 5G offers the best conditions for such state-of-the-art manufacturing systems.

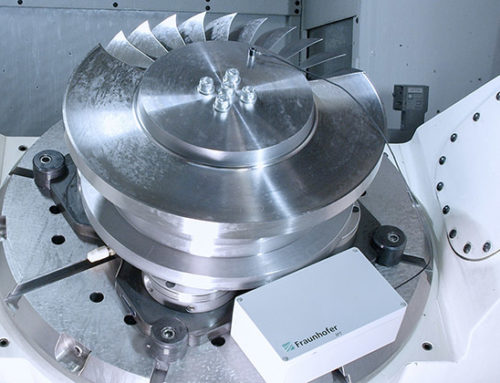

With the 5G-Industry Campus Europe, Europe’s largest industrial 5G research infrastructure went online in May 2020. Here, the Fraunhofer IPT and its research partners in Aachen are researching and testing the first industrial 5G applications. Through a total of seven subprojects, different application scenarios are being investigated, ranging from 5G sensor technology for monitoring and controlling highly complex manufacturing processes, mobile robotics and logistics, to cross-location production chains. In addition, the Aachen scientists are testing the use of modern edge-cloud systems for rapid data processing in order to exploit the potential of 5G in networked, adaptive production.

With the 5G-Audit, the partners pass on their 5G knowledge to other companies and offer support in implementing their own 5G environments. Interested companies and research partners who would like to find out more can find further information and contact persons at www.ipt.fraunhofer.de/5g-audit-en.