5G-Multisensor

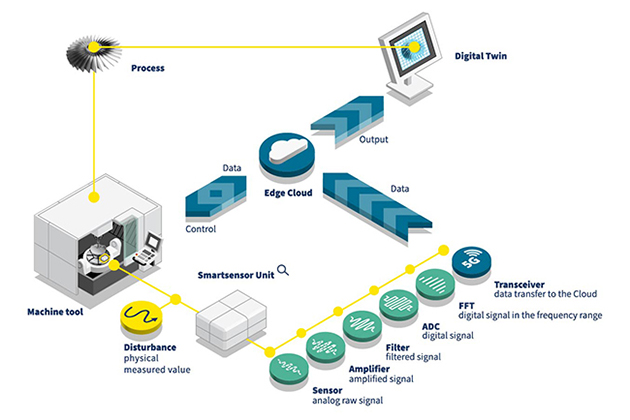

In order to control highly complex processes reliably, low latencies and component-related monitoring are required. However, current data transmission technologies, such as Bluetooth and WLAN, cannot meet industrial requirements due to excessive latency. The 5G mobile radio standard allows large amounts of data to be transmitted at high speed, enabling ultra low latencies between sensor, cloud and mainframe systems. Furthermore, 5G sensors, which are integrated close to the process on the component, capture physical data with much less interference. In the 5G-Multisensor project, a multisensor is being developed and tested on the production process of a BLISK.

5G-AE Sensor

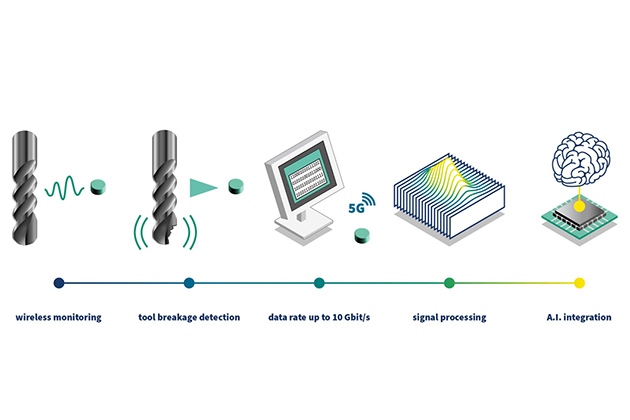

In order to monitor highly complex processes, fast reaction times are required. Process-integrated sensor technology allows various process data to be recorded and transmitted wirelessly in order to derive an adaptive manufacturing process from this constant data stream in the future.

In the 5G-AE Sensors project, tool breakage detection by wireless AE sensors is carried out in an ongoing milling operation.

5G-Blockchain

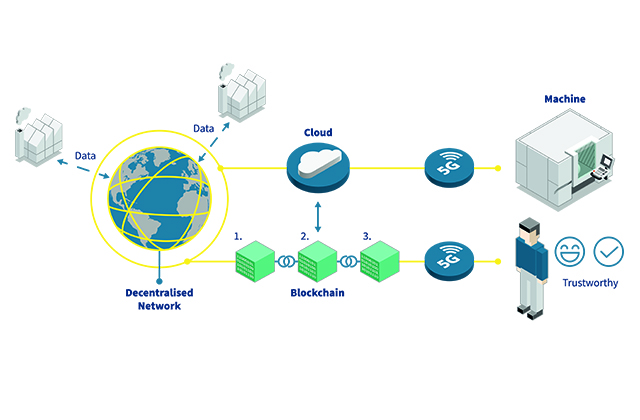

Reliable, wireless network connectivity of many data sources is a central challenge in the networking of value chains.

The aim of the 5G-Blockchain project is to test the limits of a completely wireless 5G network in a factory as part of a block-based data economy.

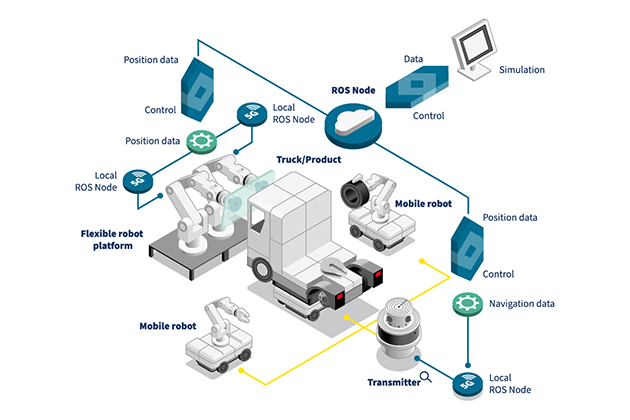

5G-Logistics

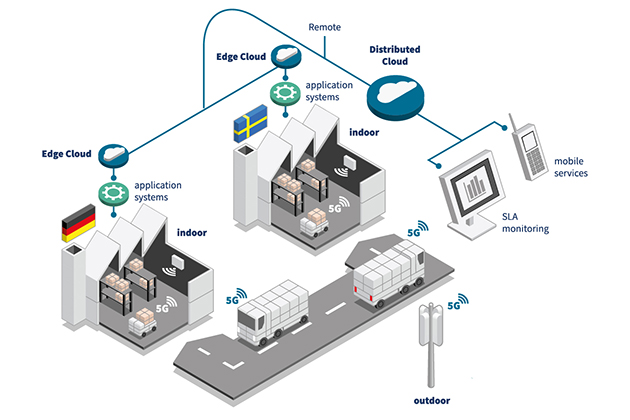

Adapting to customer requirements demands flexible, transparent and connected logistic supply chains. The increasing number of automated guided vehicle systems in workshops and logistics is raising the barriers of current wireless communication solutions in terms of data usage for sensors and control.

In order to demonstrate how 5G can be used to coordinate autonomous systems in a supply chain, an autonomous logistics solution will be set up on the 5G-Industry Campus Europe.

5G-Robotics

Flexible assembly in line-free, mobile assembly systems leads to complex, autonomous resources. The implementation of complex assembly tasks requires the synchronized processing of several robots. To ensure resource mobility and connectivity to external measurement, sensor and control systems, a wireless connection with low latency is required.

5G-Robotics objective is to create a control system for cooperating mobile robots that are connected by wireless communication.

5G-Cockpit

Production processes today take place in many different places around the world. It often happens that the same or similar production processes are carried out at different locations. This causes quality fluctuations between the individual productions.

One solution is to reliably monitor different processes and make the production process transparent. The 5G production cockpit makes it possible to collect and compare data globally on one platform and to optimize the processes accordingly. Process monitoring and data acquisition in real time via the Fraunhofer Cloud Solution to run the same optimized process at all locations.

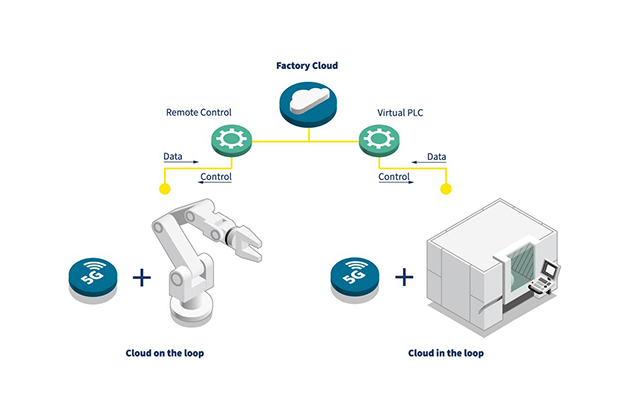

5G-Edge-Cloud

The integration of the cloud into production enables new, more intelligent and networked process chains, in the sense of Industry 4.0. The new mobile communications standard 5G, enables reliable and real-time capable communication in a factory cloud system. Complementary real-time capable computing platforms and applications must be designed and implemented for the industry.

In the 5G-Edge Cloud project, a data analysis platform with low latency in real-time for closed-loop applications in manufacturing is being created. A factory cloud system will be used that is directly connected to the 5G network.

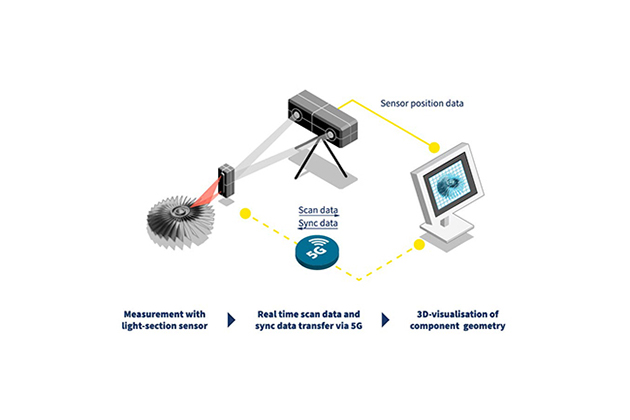

5G-3D Sensor

The 3D digitization of components has become very important in industrial metrology in the course of the trend topic “additive-manufacturing”. In order to accurately capture component geometries in three dimensions using a light-section sensor and to be able to transfer them in real time, low latencies are required to ensure synchronicity from different data sources. In the project 5G-3D Sensor the realisation of a wireless light-section sensor for 3D acquisition of components geometries is tested.