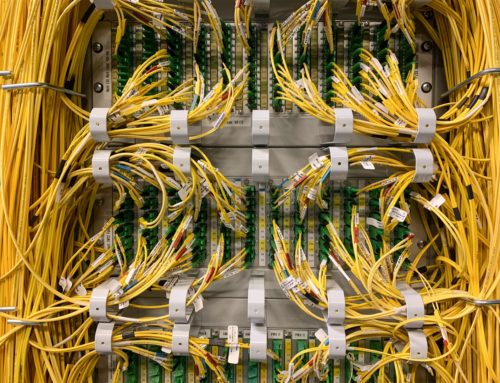

Cybersecurity has become more important than ever in the wake of increasing digitalization and networking in industrial production. More and more companies in Germany are confronted with cyber attacks from both state and private actors. The growing integration of Information Technology (IT) and Operational Technology (OT) is leading to increasingly complex digital infrastructures and thus increasing cyber security risks.

The introduction of modern technologies such as 5G, artificial intelligence and cloud computing into production environments increases the attack surface and introduces new risks into traditionally closed production systems. The complexity of digital systems is increasing, providing new vulnerabilities for attackers to disrupt production processes and cause economic damage.

Towards a secure European digital industry

To protect the European economy from these threats, the EU has introduced the new Network and Information Security Directive (NIS2), the EU Machinery Regulation and the Cyber Resiliance Act (CRA). These directives require companies to better secure their networks, information systems and products with digital elements and to increase their resilience to cyber threats. However, implementing these measures is a major challenge for many industrial companies, as both the implementation and practical testing of robust security solutions in real-world operational scenarios are time-consuming and costly. Failure to comply with these requirements can result in heavy fines, increasing the pressure on companies to act.

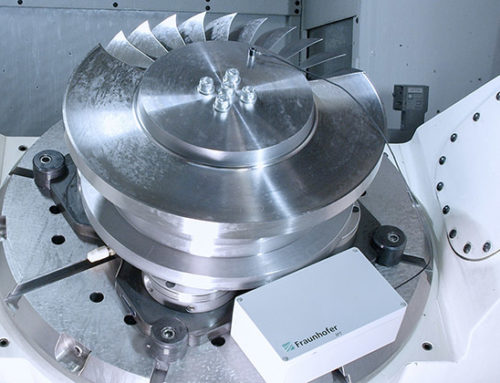

A test lab for digitally secure production

The research project “Cyber Security for Flexible and Interconnected Industry (CSII)” aims to support industrial companies – especially small and medium-sized enterprises (SMEs) – in complying with the NIS2 Directive, the EU Machinery Regulation or the CRA. The project will develop and set up an IT/OT test lab at the 5G-Industry Campus Europe in Aachen, where companies will be able to test various cybersecurity scenarios according to recognized specifications, standards and norms. After successful evaluation, the tested solutions can then be integrated into the company’s ongoing production.

In addition, the project includes the development of a new audit that enables companies to test their applications end-to-end based on national and international standards. In this way, companies can ensure that their security solutions are effective and meet the increasing demands of cyber security. In the long term, this will help to strengthen the digital security architecture in industrial production.

For more information on the project, please visit the project website: CSII project.

Project partners

- Fraunhofer Institute for Production Technology IPT, Aachen

- Uniberg GmbH, Hamburg

- Lehrstuhl für Informatik an der RWTH Aachen (SPICe), Aachen