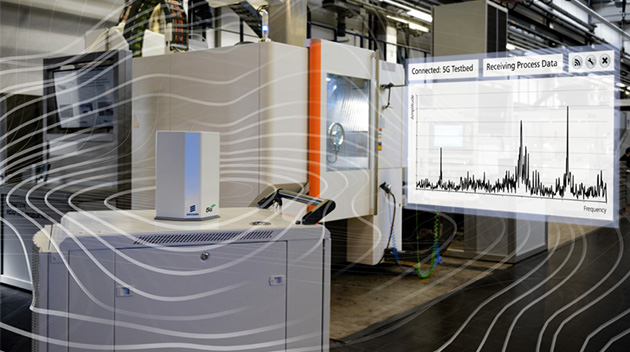

In order to test and further research sensor cloud systems in industry, the Fraunhofer IPT and seven other industrial partners are developing a modularly expandable sensor cloud system for existing machines in the “5GSensPRO” project. The system includes sensor technology, process control, evaluation, visualization software, interfaces and communication protocols to monitor and adaptively control highly dynamic production processes. In future, the system will be integrated and tested in the network of the 5G Industry Campus Europe in the Fraunhofer IPT’s machine hall, thus creating a flexible, completely wireless production environment that adds various new functions to tools and production machines.

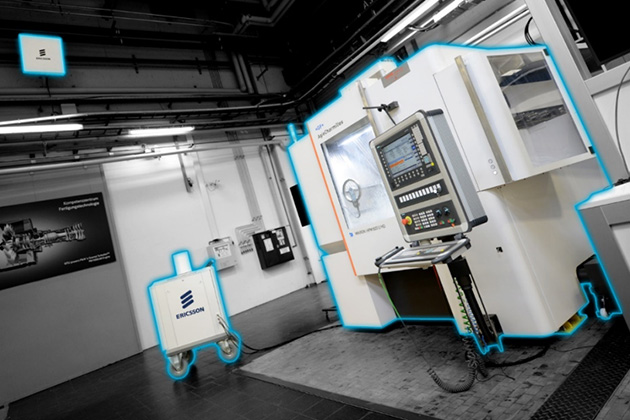

5G-SMART aims to demonstrate, evaluate and validate 5G systems for new manufacturing application in 5G-enabled industry field trials. Furthermore, the project aims to identify novel use cases, develop new 5G technology features and identify viable operator business models to drive future 5G standards and technology adaption in manufacturing ecosystem.

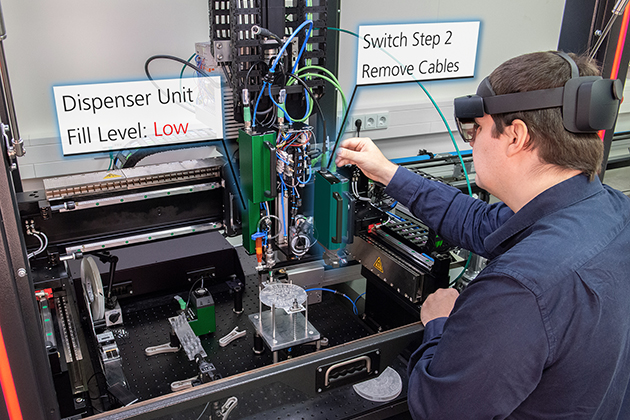

Augmented 5G

The project Augmented5G aims for connecting remote support, digital assembly and workflow-based process support with the capabilities of 5G. These use-cases are created in Augmented Reality to provide a better immersion for their tasks and allow interactivity in the process for the users. With the realiability and high bandwidth of the communication via 5G, a better quality of the AR content and interactivity with the machine is enabled.

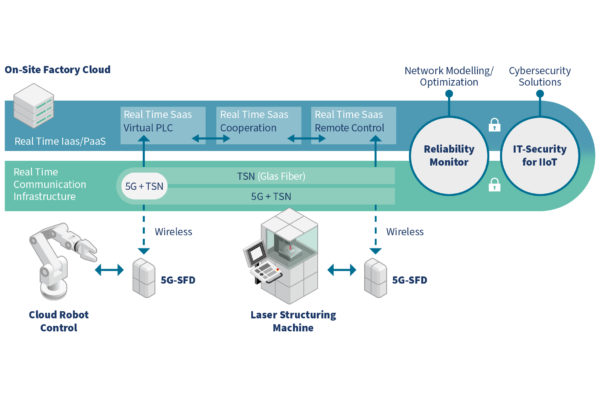

Controlling and regulating high-dynamic production systems reliably is still a challenge for many companies. In order to provide support here, edge and cloud systems are becoming increasingly important in this area, but there is often still a lack of equipment and infrastructure to integrate machines and plants into digital IT landscapes. Together with partners from the fields of mechanical engineering, network technology and robotics, the Fraunhofer IPT is developing an end-to-end real-time-capable communication infrastructure based on 5G and Time Sensitive Networking (TSN) in the 5G-Comet project. Time Sensitive Networking is a set of standards developed by the Time-Sensitive Networking Task Group that enable data transmission with low latencies and high reliability. These TSN standards will now be combined with 5G mobile technology to create an overall system with real-time capability, with the aim of creating highly available, reliable and secure communication between all components and modules: From sensors and actuators at the field level via 5G and TSN-capable networks to the Fraunhofer Edge Cloud (FEC).

In the RISEN_5G project, the Fraunhofer IPT is working with three industrial partners to develop roller burnishing tools with integrated sensors for data acquisition. Such tools are used, for example, in the pneumatics or hydraulics industry to produce high-quality surfaces of piston rods or cylinders. For the communication of the tools with adjacent monitoring or control systems, our project partners use various wireless communication technologies and evaluate them for their respective industrial use cases.

One focus is on 5G technology, with which high data rates, reliability and efficiency can be achieved. In the project, the Fraunhofer IPT is investigating different use cases with defined boundary conditions and analysing the associated requirements for data acquisition, sensor technology, and hardware and software processing. The project partners are using the 5G network of the 5G Industry Campus Europe in Aachen to test the technology.

Remote-controlled construction machines are increasingly being used in both the construction and mining sectors, and these require reliable communication via mobile communications. Especially in this sector, which has a high number of industrial accidents, a functioning and fast network is of utmost importance. The use of 5G offers new possibilities in the creation of safety concepts based on continuous real-time localization of all people and machines on the construction site or in the mine. In this way, workplace accidents can significantly be reduced and machines operated more reliably.

As part of the 5G NAMICO research project, 5G is also to be used in the construction and mining sectors of the future. Based on the findings from previous projects such as the 5G-Industry Campus Europe, a 5G network is now to be installed on a reference construction site and in an underground mine to harness the benefits of the technology. One challenge here is the adverse and changing environments: dust, vibration and humidity bring demands on a dynamic 5G network, which must withstand harsh operational conditions. 5G technology, which was developed for use in industrial environments and open areas, must therefore be developed further. The use of 5G in construction and mining has the potential to automate processes and reduce the workload of personnel. A prerequisite for this is the development of enhanced safety concepts that protect people in partially and fully automated processes, while at the same time achieving progress in digital transformation.

The TARGET-X project aims to expedite the digital transformation of critical industries, driving innovation and growth in key verticals: energy, construction, automotive, and manufacturing, using large-scale trials in multiple testbeds. By demonstrating, validating, and evaluating the potential of 5G/6G in real environments, the cutting-edge 5G/6G technologies – such as real-time communication, localization, self-description, digital twinning, and sensor-network data fusion – can undergo thorough testing and comprehensive evaluation. The evaluation focuses on KPIs, particularly KVIs such as sustainability, safety, security, and privacy. Based on these KVIs, the development of new business models and an assessment framework for economic and societal evaluation is envisioned. The process will be supported and guided by the TARGET-X community, a network of SMEs, IT- and OT-partners, and up to 100 FSTP (Financial Support for Third Parties) projects, as a strong consortium with SMEs and innovative drivers is brought together. To achieve TARGET-X’s objectives, a range of use cases for various industries within the current testbeds will be established. New 5G/6G functionalities will be developed and incorporated into these testbeds, ensuring that they are tested and validated in advanced use cases.

In recent years, more and more companies have been the target of serious cyber attacks. We are seeing a progressive digitalisation and networking in industrial production. The merging of information technology (IT) and operational technology (OT) increases the complexity of digital infrastructures, creating new cyber security risks. At the national and European level, legal measures such as the ‘Network and Information Systems (NIS) 2’ directive and the EU Machinery Regulation have been introduced. Non-compliance with these directives can result in heavy fines. However, compliance with and implementation of standards such as NIS2 often presents industrial companies with significant challenges, as they are rarely able to independently test the developed or purchased components for compliance with these directives in realistic operating environments.

The CSII project wants to address this challenge. The goal is to support industrial companies, especially SMEs, in implementing recent and future directives such as the EU Machinery Directive and NIS2. The solution involves setting up a new IT/OT test laboratory. Here, companies can test various cyber security scenarios risk-free. After evaluation, the corresponding systems can be integrated into the companies' ongoing production. In addition, the project will offer a newly developed audit that enables companies to effectively test and implement various IT security concepts according to national and international standards.